Air Separation Units

Classification:

keyword: Air Separation Units

E-mail:

WhatsAPP:

Details

This equipment adopts low-pressure technology and uses cryogenic and distillation methods to extract pure oxygen and pure nitrogen from the air. It is to use the refrigeration cycle principle of a turboexpander to liquefy air. According to the different boiling points of liquid oxygen and liquid nitrogen, secondary distillation is carried out in the fractionation tower to obtain 99.6% pure oxygen and 99.99% or higher pure nitrogen. According to the needs, changing the operation can also produce liquid oxygen, liquid nitrogen, and medical oxygen.

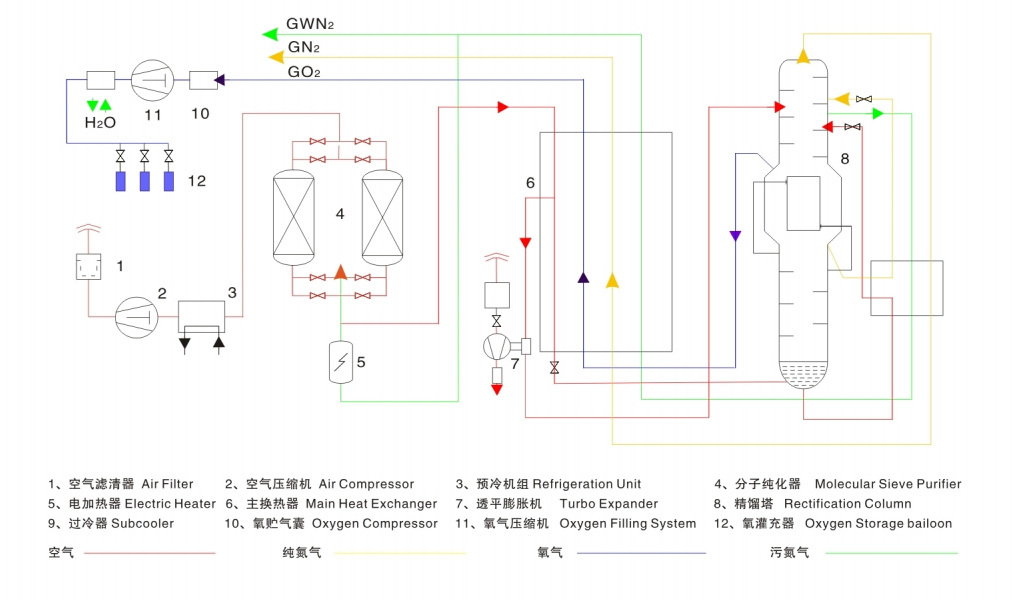

Schematic diagram of small gas air separation equipment process

1. Air compressor: The air is compressed by the air compressor to 0.5Mpa~0.7Mpa.

2. Pre-cooling: The air is pre-cooled to 5°C ~ 10°C in the pre-cooling unit and moisture is separated.

3. Purification: The air is purified in a molecular sieve to remove remaining moisture, carbon dioxide, and hydrocarbons.

4. Air expansion: The air expands in the expander to provide the cooling required by the device.

5. Heat exchange: The air exchanges heat in the main heat exchanger of the fractionation tower with returning oxygen, nitrogen, and waste nitrogen, cooling the waste nitrogen back to ambient temperature.

6. Subcooling: Liquid air and liquid nitrogen are subcooled by nitrogen and waste nitrogen in the subcooler.

7. Distillation: The air undergoes distillation separation in the lower tower, obtaining product nitrogen at the top of the upper tower.

Related Products

Leave us a message

If you have any need, please feel free to contact us