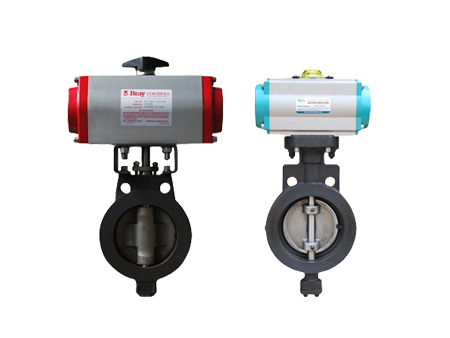

High-performance pneumatic butterfly valve

Classification:

keyword: High-performance pneumatic butterfly valve

E-mail:

WhatsAPP:

Details

High-performance pneumatic butterfly valves are fluid control devices optimized and upgraded from ordinary butterfly valves, playing a significant role in the industrial field due to their superior performance.

Structure and Principle

It uses a pneumatic actuator as its power source. Compressed air drives a piston or diaphragm, which in turn rotates the stem and disc. The valve body is usually made using precision casting, with high-strength, corrosion-resistant materials such as stainless steel and duplex steel. The disc features a streamlined design, closely fitting the valve seat to reduce fluid resistance. The valve seat uses elastic sealing materials such as EPDM and PTFE, combined with a triple-offset or double-offset structure to ensure a tight seal and achieve zero leakage.

Performance Advantages

It offers high sealing performance, maintaining good sealing even under harsh conditions of high pressure and high temperature; rapid switching, completing opening and closing actions within seconds to meet the needs of quick shutoff or adjustment; high adjustment accuracy, enabling precise control of fluid flow; high pressure resistance and wear resistance, capable of withstanding high pressure and harsh media erosion, resulting in a long service life; the pneumatic actuator also has explosion-proof capabilities, suitable for flammable and explosive hazardous environments.

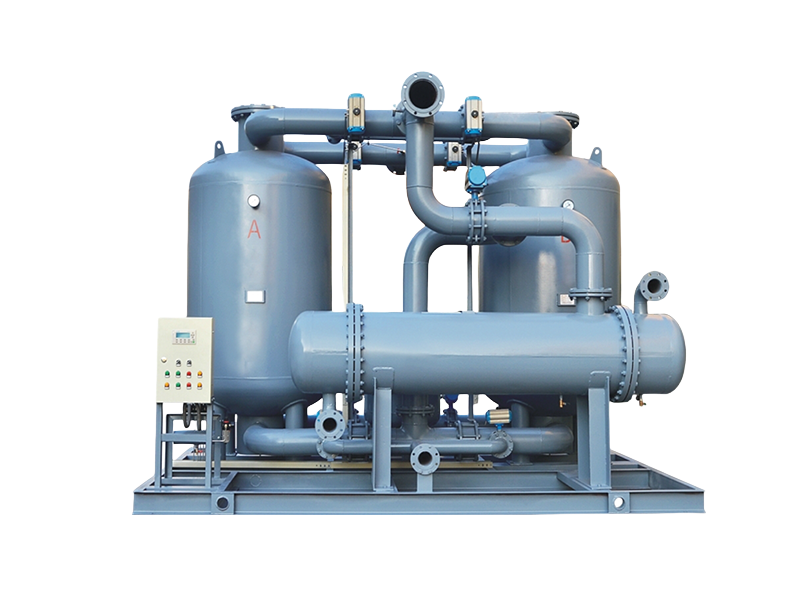

Related Products

Leave us a message

If you have any need, please feel free to contact us