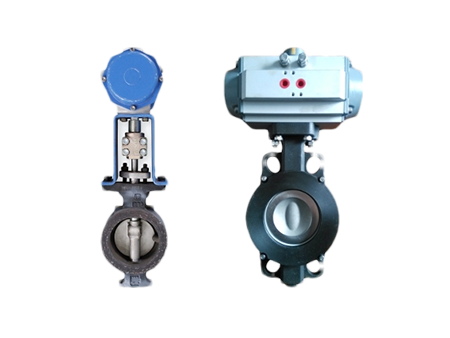

Neles-Gems butterfly valve

Classification:

keyword: Neles-Gems butterfly valve

E-mail:

WhatsAPP:

Details

A butterfly valve is a type of valve where a disc rotates around a fixed axis to control fluid flow, opening or closing the pipeline. It features simple structure, small size, light weight, easy operation, high flow capacity, and good regulation performance. It's widely used in various fields such as water supply and drainage, HVAC, chemical engineering, and power generation for shutoff and throttling applications.

Neles is a renowned valve brand, and its butterfly valves are known for their high-quality design and manufacturing. For example, the Neles Shanghai 800W series three-eccentric pneumatic butterfly valve uses a double-eccentric disc with a spherical sealing surface and a single flexible lip seal, suitable for applications requiring reliable sealing and good control characteristics. This design provides tight sealing and a long service life, allowing for quick shutoff or flow regulation. It can be used for transporting liquids and gases (including steam) in various industrial pipelines. With special selection, it can also be used for special media such as chlorine, oxygen, high vacuum, sulfur-resistant or corrosive media, and can also have a fire-resistant structure as an option. Connection methods include a wafer type or a lug-type single flange design for large diameters and pipelines ending at a terminal.

GEMÜ Group, founded in Germany in 1964, is a manufacturer of valves, measurement, and control systems. Its butterfly valve product line is extensive, offering various body materials, sealing materials, and disc materials. For example, plastic body materials include PVC-U, PP, and PES, while metal body materials include brass, cast iron, ductile iron, aluminum, and various stainless steel alloys. GEMÜ butterfly valves feature a two-piece body, a single-piece explosion-proof disc/stem, and a PFA disc liner no less than 3mm thick. This liner offers superior corrosion and temperature resistance compared to PTFE and is softer, allowing sufficient deformation for improved sealing. The disc liner is mechanically locked to the disc, and the disc center is thin cast iron to achieve high KV flow values. Additionally, the stem bushing sealing device has a self-lubricating function and provides secure pre-stressed clamping. Its applications are widespread, commonly seen in chemical and water treatment industries, and can be used with position indicators, positioners, and process controllers to achieve control functions.

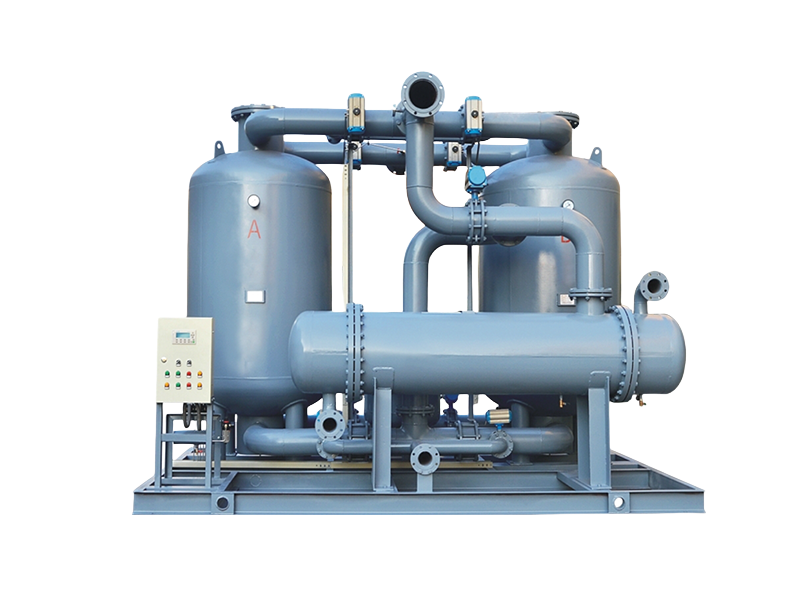

Related Products

Leave us a message

If you have any need, please feel free to contact us