Cylinder clamping device

Classification:

keyword: Cylinder clamping device

E-mail:

WhatsAPP:

Details

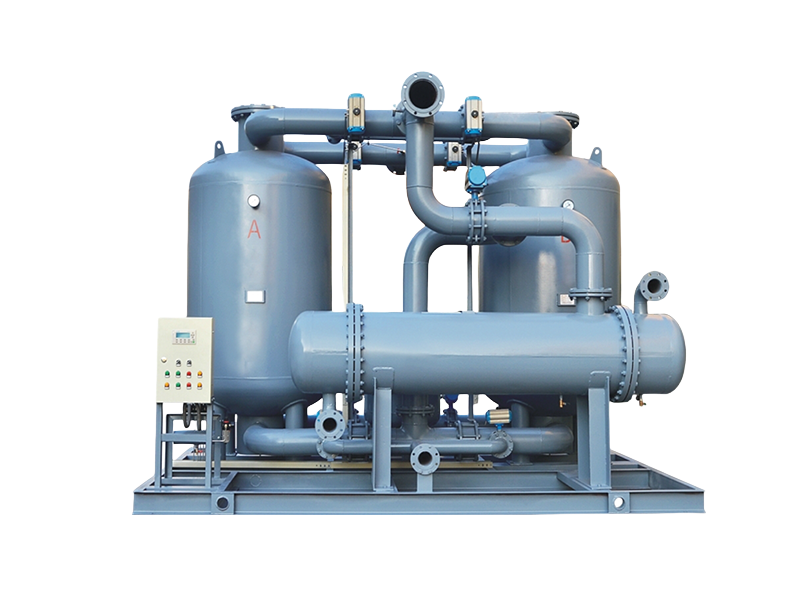

The self-acting cylinder clamping device for PSA pressure swing adsorption air separation equipment is a new technology of Juke air separation equipment. It allows the air separation to enter the working state when it starts working, and the internal piston always ensures that the molecular sieve is compressed, while not breaking the molecular sieve. It can avoid the pulverization of the molecular sieve due to the impact of different airflow directions during adsorption/desorption inside the adsorption tower, and prolong the service life of the molecular sieve.

Principle of the nitrogen generator clamping device

In the bed layer inside the separation tower, because the molecular sieve is a granular substance, it is impossible to fill it completely during the filling process. Therefore, during the operation of the separation tower, under the impact of the airflow, there is a possibility of mutual movement and friction between the molecular sieves, leading to pulverization and subsidence. Therefore, a device is needed to step-by-step compensate for the gap caused by this subsidence.

The clamping device is equipped with a settling alarm system. When the stroke of the clamping system exceeds the set lower limit, the internal cylinder piston plate contacts the alarm sensor, and the alarm contact closes. The PLC receives the input signal and automatically issues an audible and visual alarm to remind the user that the molecular sieve has reached the lower limit, so that the user can add it in time. Compared with spring clamping, coconut mat clamping, and airbag clamping devices, this clamping device has higher reliability, more convenient disassembly, and a higher degree of automation.

Level 1 Alarm

If the molecular sieve in the adsorbent compensation chamber is lower than the level 1 limit requirement, the level 1 molecular sieve limit switch will activate, prompting the user to prepare for adding molecular sieve, purchasing molecular sieve, or shutting down.

Level 2 Alarm

If the molecular sieve in the adsorbent compensation chamber continues to decrease and is lower than the level 2 limit requirement, the level 2 molecular sieve limit switch will activate, reminding the user to pay attention. If the molecular sieve is still not replenished in time, the equipment will shut down safely after 24 hours (or a time set according to customer requirements).

Related Products

Leave us a message

If you have any need, please feel free to contact us