Nitrogen generator: Provides nitrogen for the nitriding process of automotive metal components, ensuring the quality and performance of critical parts.

In the production of automotive metal components, the nitriding process is a crucial step for enhancing their performance. This process requires a stable supply of nitrogen gas, and nitrogen generators—being specialized gas-generation equipment—are perfectly suited to meet this demand, providing a continuous and reliable source of nitrogen to ensure the smooth operation of the nitriding process.

I. Nitrogen Generator Supplies Nitrogen Gas for the Nitriding Process

In the production of automotive metal components, the nitriding process is a crucial step for enhancing their performance. This process requires a stable supply of nitrogen gas, and nitrogen generators—being specialized gas-generation equipment—are perfectly suited to meet this demand, providing a continuous and reliable source of nitrogen to ensure the smooth operation of the nitriding process.

II. High-Purity Nitrogen for Oxidation and Decarburization Prevention

Nitriding processes are typically carried out under high-temperature conditions. When automotive metal components come into contact with air, they are prone to oxidation and decarburization, which can negatively impact their performance and quality. High-purity nitrogen gas produced by nitrogen generators can create a protective atmosphere around the components, effectively blocking any exposure to air and preventing oxidation and decarburization at elevated temperatures—thus paving the way for nitrogen atoms to permeate the material.

3. High-purity nitrogen gas facilitates the diffusion of nitrogen atoms

The uniform diffusion of nitrogen atoms into components to form a high-hardness layer is the core objective of the nitriding process. The purity of high-purity nitrogen gas minimizes impurities that could interfere with nitrogen atom penetration, ensuring even diffusion and infiltration of nitrogen atoms along the component's microstructure. This, in turn, leads to the formation of a uniformly thick, highly hardened layer, significantly enhancing the mechanical performance of the components.

IV. Performance of High-Purity Nitrogen Purification Components

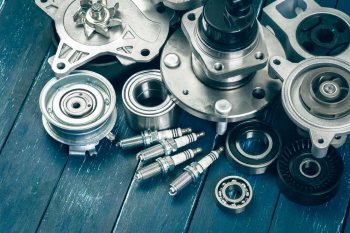

Bearings, gears, and other components are critical parts of automobiles, and their precision and wear resistance directly affect the vehicle's performance and longevity. After undergoing a nitriding process, high-purity nitrogen not only helps these components develop a highly hardened surface layer but also effectively controls deformation, ensuring they meet stringent precision requirements—while significantly enhancing wear resistance, reducing operational wear, and ultimately extending the lifespan of the parts.

V. High-Purity Nitrogen Ensures Core Quality

The quality of a vehicle's core components determines the overall performance and safety of the entire car. Nitrogen generators supply high-purity nitrogen gas for the nitriding process, ensuring improved performance of metal parts right from the source of manufacturing. This guarantees that critical components such as bearings and gears meet stringent standards in terms of precision, hardness, and wear resistance, providing crucial support for the quality of automotive core parts—and laying a solid foundation for the vehicle's overall quality and reliability.

Other areas

Oil storage and pressurized pipeline cleaning and purging of oil and gas wells, nitrogen sealing, nitrogen displacement, solvent recovery.

Used for food preservation and grain storage, pest control, food drying and sterilization, quick freezing of food, etc.

Provide the necessary gas raw materials for the preparation of new energy materials, battery production, and create an inert gas environment.

Ensure the manufacturing of electronic components and the stable operation of equipment, providing gas support for maintenance, combustion assistance, cooling, and other aspects related to thermal power generation equipment.

Nitrogen generator: Prevents oxidation, inhibits bacterial growth, and produces odors in biopharmaceuticals, providing protection throughout the process. Oxygen generator: Provides an oxygen-rich environment.

When signs of fire occur in the goaf or other locations, nitrogen injection is needed for fire prevention. The nitrogen device is lowered into the mine. It is used for annealing protective gas and sintering.

Used in the aerospace composite field, providing the necessary inert atmosphere for the molding and reinforcement processes of large carbon fiber composite wings.

Provide protection for the safety of oil and gas reserves, prevent oxidation, nitrogen sealing, and ensure dust suppression, fire prevention, and nitrogen sealing for coal reserves.