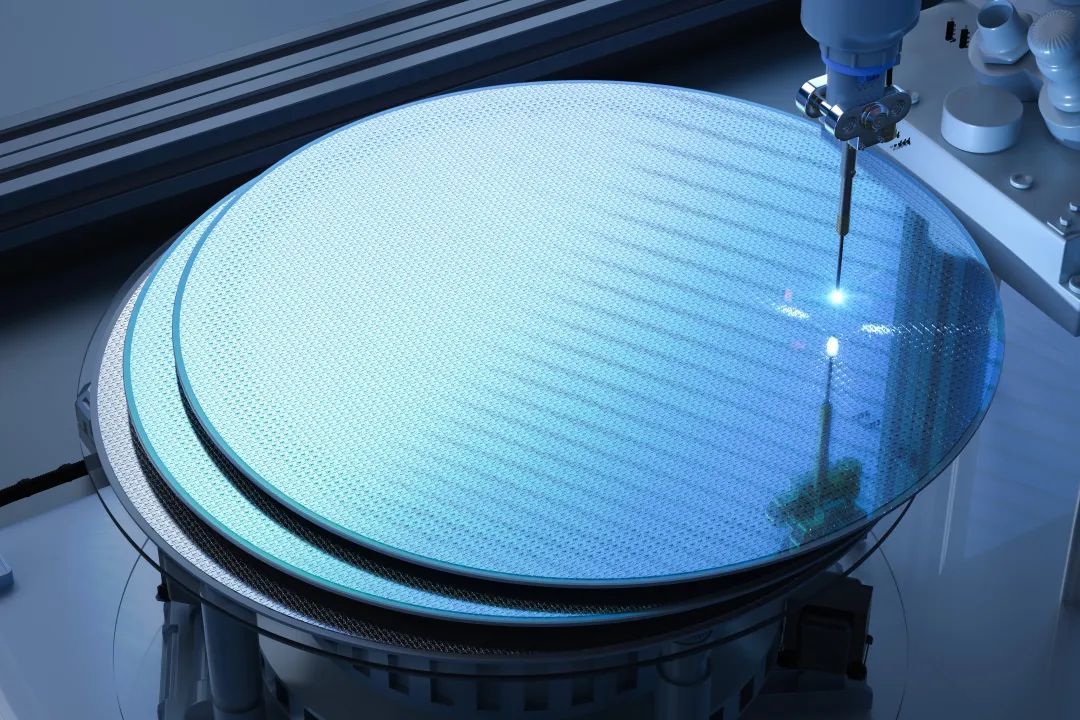

Application scenarios of nitrogen generators in wafer production, packaging, and transportation

Nitrogen generators have a wide range of applications in wafer production, packaging, and transportation.

In today's booming semiconductor industry, wafers, as core basic components, require crucial quality assurance throughout their production, packaging, and transportation processes. The high-purity nitrogen provided by nitrogen generators plays a key role in wafer-related processes due to its stable chemical properties and its resistance to reactions with other substances.

I. Wafer Production Stages

(1) Photolithography

Photolithography is a crucial step in wafer production, demanding extremely high environmental purity. The high-purity nitrogen (purity often exceeding 99.999%) produced by nitrogen generators is used for atmosphere protection in the photolithography area. On the one hand, it effectively removes oxygen, preventing photoresist oxidation during exposure, which would affect the accuracy and resolution of pattern transfer. Studies have shown that in a high-purity nitrogen environment, the roughness of the photoresist line edges can be reduced, resulting in clearer and more precise chip circuit patterns, thus improving chip performance and integration. On the other hand, nitrogen can remove heat generated during photolithography, stabilizing the operating temperature of the photolithography equipment and ensuring the stability and consistency of the photolithography process.

(2) Etching Process

In the etching process, the nitrogen provided by the nitrogen generator is used for multiple purposes. Firstly, as a carrier gas, it carries the etching gas uniformly to the wafer surface, ensuring uniformity in the etching process. For example, in plasma etching, nitrogen can precisely control the flow rate and distribution of the etching gas, making the etching rate consistent across different parts of the wafer surface. This minimizes the error in wafer surface etching uniformity, improves the accuracy of the etched circuit, and ensures the precise formation of the microstructures on the chip. Secondly, nitrogen creates an inert environment during etching, preventing the accidental oxidation of materials on the wafer surface or the introduction of other impurities during etching. This maintains the purity of the wafer surface and lays a good foundation for subsequent process steps.

(3) Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD)

CVD Process: In the CVD process, nitrogen plays multiple roles. It not only acts as a carrier gas, stably transporting precursor chemicals to the wafer surface to promote chemical reactions and form solid material films on the wafer, such as silicon nitride (Si₃N₄) films with excellent insulation and chemical stability, improving the performance and reliability of semiconductor devices; it can also dilute the reactant gas, adjust the reaction rate, and ensure the controllability of the film growth process, effectively ensuring the uniformity and quality of the deposited film thickness.

PVD Process: In PVD, nitrogen is used in the sputtering process. For example, when preparing metal nitride films, nitrogen reacts with the sputtered metal atoms to form the required metal nitride coating on the wafer surface. At the same time, the high-purity nitrogen environment prevents oxidation of the metal atoms and the wafer surface during sputtering, ensuring the purity and performance of the coating and improving the electrical and optical properties of the wafer in subsequent applications.

(4) Annealing Process

Annealing is an important process for improving the performance of wafer materials. During high-temperature annealing, the high-purity nitrogen provided by the nitrogen generator creates an inert protective atmosphere to prevent the oxidation of wafers such as silicon wafers. The presence of oxygen will cause an oxide layer to form on the wafer surface, affecting the electrical properties of the material. Under nitrogen protection, this oxidation phenomenon can be avoided, reducing impurity introduction and maintaining the integrity of the crystal structure inside the wafer. This optimizes the electrical properties of the material, such as reducing resistivity and increasing electron mobility, thereby improving the overall performance of the chip.

II. Wafer Packaging Stage

(1) Packaging Material Protection

During wafer packaging, if epoxy resins and other packaging materials come into contact with oxygen during curing, oxidation reactions are likely to occur, resulting in defects such as bubbles, affecting the density and reliability of the packaging structure. The nitrogen provided by the nitrogen generator fills the packaging cavity, isolating oxygen and inhibiting the reaction between the epoxy resin and oxygen, significantly reducing the bubble rate in the packaging and making the packaging structure more dense. For example, after adopting nitrogen protection, a certain packaging plant reduced its packaging bubble rate from 0.8% to 0.05%, improving the density of the packaging structure by 40%, effectively enhancing the protective effect of the packaging on the wafer and improving the stability and service life of the chip in complex environments.

(2) Preventing Metal Interconnect Oxidation

Aluminum, copper, and other metal interconnect wires inside the chip are prone to oxidation reactions with oxygen during packaging, increasing resistivity and affecting signal transmission stability. The nitrogen generator provides a nitrogen environment with a purity ≥99.999%, effectively preventing metal interconnect oxidation. Studies have shown that under nitrogen protection, the defect rate of metal interconnect oxidation is significantly reduced. For example, after adopting nitrogen protection, a certain storage chip packaging plant reduced the metal interconnect oxidation defect rate from 0.5% to 0.03%, while reducing resistivity by 30% and improving signal transmission stability by 20%, ensuring efficient and stable transmission of internal signals in the chip.

III. Wafer Transportation Stage

(1) Preventing Moisture Corrosion

Wafers are extremely sensitive to environmental humidity. Moisture during transportation can easily lead to problems such as solder joint corrosion, affecting wafer performance. Filling the wafer transport box with nitrogen generated by a nitrogen generator can reduce the humidity inside the box. For example, after filling the LED chip transport box with nitrogen, the humidity dropped from 30% RH to 5% RH, effectively preventing moisture corrosion of the solder joints and wafer surface and preventing electrical performance failures such as short circuits and open circuits caused by moisture, ensuring that the wafer performance is not affected during transportation and that it can be used normally upon arrival at its destination.

(2) Reducing the Impact of Vibration and Shock

Although nitrogen itself cannot directly reduce vibration and shock during transportation, filling the transport box with nitrogen can create a certain buffer space, reducing direct collisions between the wafer and the inner wall of the transport box. At the same time, the inert environment of nitrogen can prevent oxidation caused by frictional heat from minor collisions, further protecting the integrity of the wafer during transportation and reducing the wafer defect rate caused by physical damage and chemical changes during transportation.

In summary, nitrogen generators play an irreplaceable role in the entire process of wafer production, packaging, and transportation. By providing high-purity nitrogen, they effectively address key issues such as oxidation, contamination, and humidity that affect wafer quality and performance, providing solid support for the high-quality development of the semiconductor industry. As semiconductor technology continues to develop towards higher precision and smaller sizes, the requirements for the performance and purity of nitrogen generators will continue to increase. The application prospects of nitrogen generators in wafer-related fields will be even broader, and their technological innovation will continue to drive the progress of the semiconductor industry.

Other areas

Oil storage and pressurized pipeline cleaning and purging of oil and gas wells, nitrogen sealing, nitrogen displacement, solvent recovery.

Used for food preservation and grain storage, pest control, food drying and sterilization, quick freezing of food, etc.

Provide the necessary gas raw materials for the preparation of new energy materials, battery production, and create an inert gas environment.

Ensure the manufacturing of electronic components and the stable operation of equipment, providing gas support for maintenance, combustion assistance, cooling, and other aspects related to thermal power generation equipment.

Nitrogen generator: Prevents oxidation, inhibits bacterial growth, and produces odors in biopharmaceuticals, providing protection throughout the process. Oxygen generator: Provides an oxygen-rich environment.

When signs of fire occur in the goaf or other locations, nitrogen injection is needed for fire prevention. The nitrogen device is lowered into the mine. It is used for annealing protective gas and sintering.

Used in the aerospace composite field, providing the necessary inert atmosphere for the molding and reinforcement processes of large carbon fiber composite wings.

Provide protection for the safety of oil and gas reserves, prevent oxidation, nitrogen sealing, and ensure dust suppression, fire prevention, and nitrogen sealing for coal reserves.