Knowledge Sharing: Does the nitrogen generation mechanism obtain gaseous nitrogen or liquid nitrogen?

Normally, the nitrogen generation methods we refer to produce gaseous nitrogen. If liquid nitrogen is needed, cryogenic air separation equipment must be used.

Nitrogen Generator: Produces gaseous nitrogen using pressure swing adsorption technology

Nitrogen generators are widely used in industrial settings, their core operating principle based on pressure swing adsorption (PSA) technology. The adsorbent (such as molecular sieve) inside the equipment has a special selective adsorption capacity, preferentially adsorbing oxygen, carbon dioxide, and other impurity gases in the air under specific pressure, while nitrogen passes through smoothly. When the pressure is reduced, the adsorbed impurities are released, completing the regeneration cycle. The entire process does not require a complex refrigeration system, directly producing high-purity gaseous nitrogen, with purity typically between 95% and 99.999%. This gaseous nitrogen can be directly connected to the production line to meet the immediate gas needs of food preservation, electronic component welding, etc., and the equipment starts quickly and occupies a small area, making it very suitable for small and medium-scale nitrogen consumption scenarios.

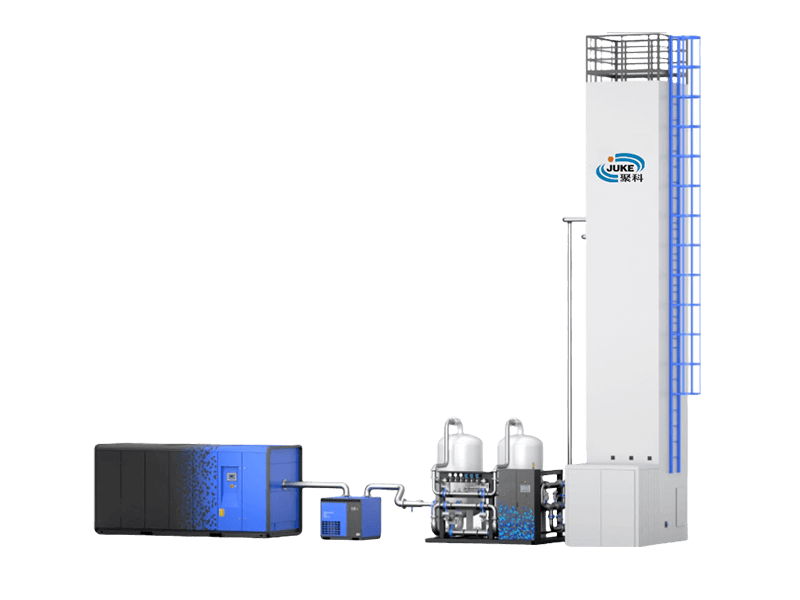

Cryogenic Air Separation Unit: Produces liquid nitrogen through deep refrigeration

The production of liquid nitrogen relies on cryogenic air separation units, with a more complex technical path, the core of which is to separate air components based on the differences in their boiling points. First, the air undergoes compression and purification to remove moisture, dust, and other impurities; then it enters a deep refrigeration system and is cooled to around -196℃—this temperature is close to the boiling point of nitrogen, causing the air to gradually liquefy. In the distillation column, using the difference in boiling points between nitrogen (-196℃) and oxygen (-183℃), repeated evaporation and condensation are used to separate nitrogen from other gases, ultimately obtaining liquid nitrogen. This equipment can not only produce liquid nitrogen but also simultaneously produce liquid oxygen and other products, and is the main way to obtain liquid nitrogen on a large scale.

Application Scenarios: Different suitable fields for gaseous nitrogen and liquid nitrogen

Gaseous nitrogen produced by nitrogen generators, due to its immediate supply and flexible equipment, is more suitable for small and medium-scale, continuous gas use scenarios. For example, in chemical production as an inert protective gas to prevent material oxidation, in food packaging to displace air and extend shelf life, or in tire manufacturing to replace air filling to improve stability. Liquid nitrogen, due to its low-temperature characteristics and easy storage and transportation (requires special cryogenic storage tanks), is mainly used in scenarios requiring low-temperature environments or large amounts of nitrogen: in the medical field for cryotherapy and preservation of biological samples, in metal processing as a low-temperature quenching medium, in scientific research experiments to simulate extreme low-temperature environments, and in large-scale cold chain logistics for emergency refrigeration, etc.

Technical Path Determines Form: The essential difference and synergistic value of the two

The difference in nitrogen production forms between nitrogen generators and cryogenic air separation units essentially stems from different technical paths. Nitrogen generators obtain gaseous nitrogen directly through "room temperature adsorption separation," emphasizing immediacy and flexibility; cryogenic air separation units separate liquid nitrogen through "deep refrigeration liquefaction," emphasizing large-scale production and the utilization of special physical properties. In practical applications, the two are not mutually exclusive: small enterprises can use nitrogen generators to meet their daily gaseous nitrogen needs, while large factories or liquid nitrogen suppliers rely on cryogenic air separation units for large-scale production. Understanding this difference can help users choose the most suitable nitrogen acquisition scheme based on their own production capacity, gas use form, and cost budget.

Other areas

Oil storage and pressurized pipeline cleaning and purging of oil and gas wells, nitrogen sealing, nitrogen displacement, solvent recovery.

Used for food preservation and grain storage, pest control, food drying and sterilization, quick freezing of food, etc.

Provide the necessary gas raw materials for the preparation of new energy materials, battery production, and create an inert gas environment.

Ensure the manufacturing of electronic components and the stable operation of equipment, providing gas support for maintenance, combustion assistance, cooling, and other aspects related to thermal power generation equipment.

Nitrogen generator: Prevents oxidation, inhibits bacterial growth, and produces odors in biopharmaceuticals, providing protection throughout the process. Oxygen generator: Provides an oxygen-rich environment.

When signs of fire occur in the goaf or other locations, nitrogen injection is needed for fire prevention. The nitrogen device is lowered into the mine. It is used for annealing protective gas and sintering.

Used in the aerospace composite field, providing the necessary inert atmosphere for the molding and reinforcement processes of large carbon fiber composite wings.

Provide protection for the safety of oil and gas reserves, prevent oxidation, nitrogen sealing, and ensure dust suppression, fire prevention, and nitrogen sealing for coal reserves.