Knowledge Sharing: The Impact of Temperature on Nitrogen Production Rate of Hollow Fiber Membranes

Hollow fiber membrane is an important nitrogen production component of membrane separation nitrogen generators, and temperature affects the nitrogen production efficiency of hollow fiber membranes.

In membrane nitrogen generation technology, the hollow fiber membrane serves as the core nitrogen production component, and its performance directly affects the nitrogen production efficiency of the equipment. Temperature, as a key environmental factor, has a significant impact on the nitrogen production rate of the hollow fiber membrane. This impact has a clear scientific mechanism.

Arrhenius Relationship: The Core Law Governing Temperature's Influence

The rate of gas permeation through the hollow fiber membrane follows the Arrhenius relationship, which is an important basis for understanding the influence of temperature on the nitrogen production rate. The Arrhenius relationship is an important law in chemistry and materials science that describes the relationship between reaction rate or diffusion rate and temperature. Its core content is: there is an exponential function relationship between the rate constant and temperature; when the temperature increases, the rate constant usually increases. This relationship can be expressed mathematically as

k = A e^{-E_a/(RT)}

Where k is the rate constant, A is the pre-exponential factor, E a is the activation energy, R is the gas constant, and T is the temperature. In the process of gas permeation through the membrane, this relationship means that changes in temperature will directly affect the rate of gas permeation through the membrane. When the temperature increases, within a certain range, the rate of gas permeation through the membrane will increase accordingly.

Specific Mechanism of Temperature's Influence on Nitrogen Production Rate

From the perspective of molecular motion, changes in temperature will directly affect gas molecules and the membrane material itself. Within a reasonable temperature range, an increase in temperature will cause gas molecules to gain more energy, their thermal motion becomes more intense, their diffusion capacity increases, thereby accelerating the speed of gas molecules permeating the membrane.

At the same time, the segmental movement of the membrane material will also become more active due to the increase in temperature, and the microstructure of the membrane will undergo a certain degree of adjustment, making the passage channels for nitrogen molecules within the membrane more unobstructed, further promoting nitrogen permeation. The combined effect of these two aspects leads to an increase in the permeation rate of nitrogen within this temperature range.

Boundary Conditions of Temperature's Influence

However, it should be clarified that the promoting effect of temperature on the nitrogen production rate of the hollow fiber membrane is not unlimited. When the temperature exceeds a reasonable range, excessively high temperatures may adversely affect the structure of the membrane material, leading to a decrease in the stability of the membrane's performance, and may even cause aging or damage to the membrane material, which in turn will reduce the permeation rate of nitrogen and affect the normal operation and nitrogen production efficiency of the equipment.

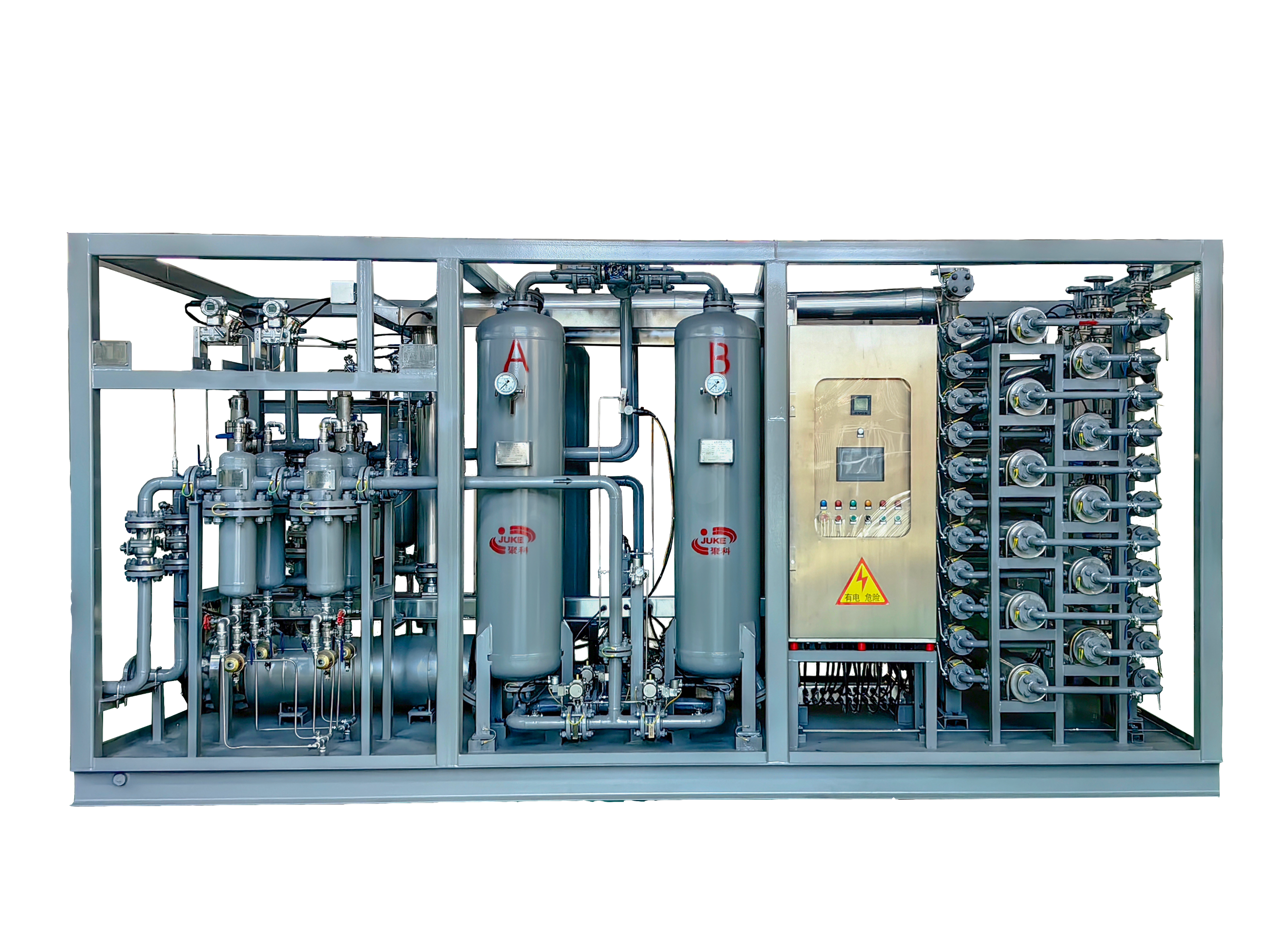

Temperature Control Scheme for JuKe Membrane Separation Nitrogen Generator

Based on in-depth research and accurate understanding of the relationship between temperature and the nitrogen production rate of hollow fiber membranes, JuKe fully considers the influence of temperature factors in the design and production of membrane separation nitrogen generators.

To ensure that the equipment always operates under suitable temperature conditions, JuKe adds insulation materials to the membrane separation nitrogen generator according to the actual situation such as the equipment's operating environment and operating conditions. These insulation materials can effectively reduce the heat exchange between the equipment and the external environment, maintain the stability of the internal temperature of the equipment, and avoid adverse effects on the membrane's performance due to excessive fluctuations in ambient temperature.

In addition, JuKe's membrane separation nitrogen generators are also equipped with electric air heaters. When the ambient temperature is low and may affect the normal operating temperature of the membrane, the electric air heater can be used to heat the air entering the equipment, keeping the temperature of the gas entering the hollow fiber membrane within a suitable range, thereby ensuring that the diffusion of gas molecules and the segmental movement of the membrane material are in an ideal state, ensuring that the permeation rate of nitrogen remains stable at a high level, and thus ensuring that the equipment has high nitrogen production efficiency.

Through these targeted designs and configurations, JuKe's membrane separation nitrogen generators can effectively cope with the impact of temperature changes and maintain stable and efficient nitrogen production performance under different operating conditions, providing reliable support for the nitrogen usage needs of various industries.

Other areas

Oil storage and pressurized pipeline cleaning and purging of oil and gas wells, nitrogen sealing, nitrogen displacement, solvent recovery.

Used for food preservation and grain storage, pest control, food drying and sterilization, quick freezing of food, etc.

Provide the necessary gas raw materials for the preparation of new energy materials, battery production, and create an inert gas environment.

Ensure the manufacturing of electronic components and the stable operation of equipment, providing gas support for maintenance, combustion assistance, cooling, and other aspects related to thermal power generation equipment.

Nitrogen generator: Prevents oxidation, inhibits bacterial growth, and produces odors in biopharmaceuticals, providing protection throughout the process. Oxygen generator: Provides an oxygen-rich environment.

When signs of fire occur in the goaf or other locations, nitrogen injection is needed for fire prevention. The nitrogen device is lowered into the mine. It is used for annealing protective gas and sintering.

Used in the aerospace composite field, providing the necessary inert atmosphere for the molding and reinforcement processes of large carbon fiber composite wings.

Provide protection for the safety of oil and gas reserves, prevent oxidation, nitrogen sealing, and ensure dust suppression, fire prevention, and nitrogen sealing for coal reserves.