Full of dry goods!! Membrane nitrogen generator vs. PSA nitrogen generator: Differences and industrial choices in industrial nitrogen generation

This document details the differences in operating principles between membrane nitrogen generators and PSA nitrogen generators, and provides suggestions for selection in industrial production.

In the vast field of industrial production, nitrogen, as a crucial industrial gas, plays a key role in numerous industries such as chemical, electronics, food, and pharmaceuticals, owing to its inertness, non-corrosiveness, and stable chemical properties. To meet the demand for nitrogen, membrane nitrogen generators and PSA nitrogen generators have become commonly used on-site nitrogen production equipment. So, what are the advantages and disadvantages of these two types of nitrogen generators? How should we choose in industrial production? Let's explore this further.

I. Unveiling the Working Principles

(I) Membrane Nitrogen Generator

Membrane nitrogen generators utilize gas permeation membrane technology. When air passes through a semi-permeable membrane, due to the differences in the diameters and kinetic properties of different gas molecules, their permeation rates also vary. Nitrogen molecules are relatively small and more easily permeate the membrane, while oxygen molecules and other larger molecules are less likely to permeate. In this way, relatively low-purity nitrogen gas can be obtained. Specifically, under the action of pressure difference on both sides of the membrane, the solubility and diffusion coefficient of nitrogen and oxygen in the membrane are different. Gases such as water vapor and oxygen with faster permeation rates pass through the membrane first, becoming oxygen-rich gas, while nitrogen with slower permeation rate remains and accumulates, becoming dry nitrogen-rich gas, thus achieving oxygen-nitrogen separation.

(II) PSA Nitrogen Generator

PSA nitrogen generator stands for Pressure Swing Adsorption Nitrogen Generator. It utilizes the difference in the "adsorption" performance of molecular sieves for different gas molecules to separate gases. Using air as a raw material, it leverages the selective adsorption performance of a high-efficiency, high-selectivity solid adsorbent for nitrogen and oxygen to separate nitrogen and oxygen from the air. Under high pressure, oxygen and other gases are preferentially adsorbed by the molecular sieve, while nitrogen passes through as the product gas; when the adsorbent reaches adsorption saturation, the pressure is reduced to desorb the adsorbed gas, thus regenerating the adsorbent, and this cycle is repeated to continuously produce nitrogen.

II. Performance Differences

(I) Nitrogen Purity

Membrane Nitrogen Generator: Under normal circumstances, the nitrogen purity produced by membrane nitrogen generators is generally between 95% and 99%. While this can meet the needs of some fields with relatively low nitrogen purity requirements, its application is limited in industries with strict requirements for nitrogen purity, such as electronics, semiconductors, food packaging, healthcare, chemicals, and metal heat treatment. However, under certain specific processes or after special design, its nitrogen purity can also reach 99.9%.

PSA Nitrogen Generator: With high-efficiency adsorbents, PSA nitrogen generators excel in providing high-purity nitrogen, capable of producing nitrogen with a purity as high as 99.999%. This advantage gives it a significant advantage in industries with demanding nitrogen purity requirements, making it the choice for many high-end industrial applications.

(II) Equipment Weight and Floor Space

Membrane Nitrogen Generator: The nitrogen generator host is relatively light and has a compact overall structure, occupying a small footprint. Its lightweight design makes it easier to install in confined spaces, such as laboratory workbenches, trucks, and offshore drilling platforms, and facilitates flexible layout in industrial scenarios with high space requirements.

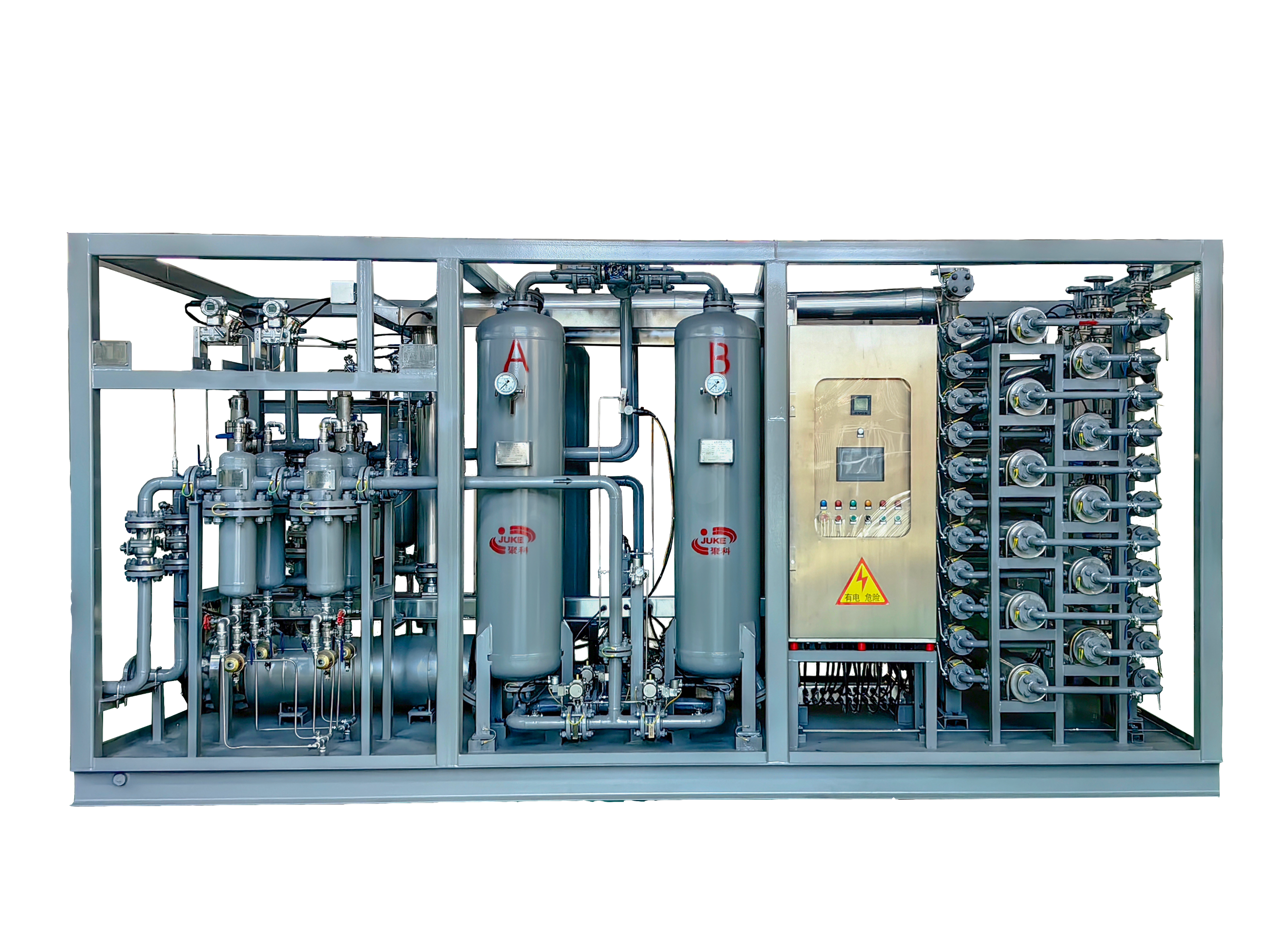

PSA Nitrogen Generator: Due to its internal structure, including double towers, compressors, and air storage tanks, the nitrogen generator host is usually heavier and occupies a larger footprint. However, with the development of technology, modular PSA skids have become increasingly popular, improving the flexibility and scalability of its layout to some extent. However, overall, in terms of equipment weight and floor space, PSA nitrogen generators are still at a disadvantage compared to membrane nitrogen generators.

(III) Required Airflow and Energy Consumption

Membrane Nitrogen Generator: Requires a relatively large amount of air, especially when pursuing higher nitrogen purity. To meet the separation requirements, a larger airflow is often needed, which can increase the operating cost to some extent. However, due to its continuous low-pressure air operation and the absence of adsorption/desorption cycles, energy consumption is usually lower during the production of medium and low purity nitrogen, with relatively low energy consumption per 1Nm³ of nitrogen produced.

PSA Nitrogen Generator: Requires relatively less airflow, but when the purity level is above 98%, its operating cost efficiency is significantly higher than the membrane separation system. Because in the production of high-purity nitrogen, PSA nitrogen generators need to frequently switch adsorption towers and regenerate adsorbents, these processes consume more energy. However, with the expansion of the system scale and the optimization of compressors, its energy efficiency in large-scale high-purity nitrogen production will improve.

(IV) Startup Time and Response Speed

Membrane Nitrogen Generator: It has the characteristic of instantaneous startup, with extremely short preheating time. It can produce qualified nitrogen gas in about 10 minutes after startup, and can output nitrogen gas almost instantly. This rapid response capability makes it very suitable for mobile equipment, intermittent use, or facilities that need to quickly obtain nitrogen on demand, such as in some emergency nitrogen supply scenarios where it can quickly play a role.

PSA Nitrogen Generator: It takes a few minutes to stabilize after startup, but once stable, it can provide precise flow control to achieve continuous and adjustable nitrogen supply. This stability and precision are particularly important for high-purity processes or production lines with continuous demand, ensuring the stability and reliability of nitrogen supply during production.

(V) Maintenance Cost

Membrane Nitrogen Generator: Due to its few internal moving parts, low mechanical wear, and long service intervals, maintenance mainly focuses on regular maintenance of air filters, activated carbon filters, etc., without the need for professional technicians to perform complex maintenance operations. Therefore, the maintenance cost is low, making it very suitable for unattended or remote applications.

PSA Nitrogen Generator: Although the equipment structure and working principle are relatively simple, there is a certain maintenance requirement due to the involvement of adsorption tower switching, valve actions, and compressor operation. For example, regular maintenance and servicing of air filters, dryers, etc., replacement of wearing parts, and the carbon molecular sieve adsorbent has a certain service life (generally 5-8 years). Although ordinary technicians can perform maintenance operations after simple training, the overall maintenance cost is still higher than that of membrane nitrogen generators.

(VI) Equipment Cost

Membrane nitrogen generators: Due to their simple design, lack of complex moving parts and control systems, their initial investment is typically lower. This is quite attractive for small businesses with limited budgets or those with low nitrogen demands, allowing them to meet their basic nitrogen needs at a lower cost.

PSA nitrogen generators: Especially in high-purity configurations and with backup compressors, the initial cost is higher. This is because the equipment is relatively complex and requires high-quality adsorbents, reliable valves, and stable-performance compressors to ensure stable output of high-purity nitrogen. However, in the long-term, large-scale production of high-purity nitrogen, the relatively low operating costs make the total cost of ownership (TCO) more advantageous.

III. Selection Strategies in Industrial Production

(1) Selection Based on Nitrogen Purity Requirements

If industrial production requires extremely high nitrogen purity, such as in the manufacturing of electronic components, semiconductor production, high-end food packaging, and pharmaceuticals, where purity greater than 99.5% or even higher is needed, PSA nitrogen generators are undoubtedly a better choice. They can stably produce high-purity nitrogen, meeting the strict requirements of these industries for product quality and compliance.

For applications with nitrogen purity requirements between 90% and 99%, such as tire inflation, fire suppression systems, nitrogen inerting in oil and gas, general nitrogen filling, and offshore and mobile applications, membrane nitrogen generators can effectively meet production needs with their moderate purity and other advantages.

(2) Selection Combining Production Scale and Flow Rate Requirements

When a company uses a large amount of nitrogen and requires a continuous and stable supply, with high precision requirements for flow control, PSA nitrogen generators are more suitable. For example, in large-scale industrial production in large chemical plants and steel mills, PSA nitrogen generators can meet the continuous demand for large flow rates and high-purity nitrogen through reasonable system configuration.

If a company's nitrogen demand is intermittent, relatively small, or requires rapid response, such as in small laboratories, temporary nitrogen supply in mining, and aquatic product preservation, the rapid start-up and flexible supply characteristics of membrane nitrogen generators make them an ideal choice, quickly meeting temporary nitrogen needs during production.

(3) Selection Considering Cost Factors

In terms of initial investment cost, membrane nitrogen generators have a clear advantage, suitable for companies with limited funds or short-term projects. However, from the perspective of long-term operating costs and total cost of ownership (TCO), for companies that need to produce large quantities of high-purity nitrogen for a long time, PSA nitrogen generators, although having higher initial investment, have relatively lower operating costs in high-purity nitrogen production, making them more cost-effective in the long run.

In addition, energy consumption costs need to be considered. In the production of medium and low purity nitrogen, membrane nitrogen generators have lower energy consumption; while in large-scale high-purity nitrogen production, as the scale of the PSA nitrogen generator system expands and technology is optimized, its energy consumption costs can also be well controlled, and the benefits brought by the high-quality nitrogen produced can offset some of the energy consumption costs.

(4) Selection Focusing on Installation Space and Maintenance Convenience

If a company has limited installation space or the equipment needs to be portable, such as on offshore platforms or mobile work vehicles, the compact structure and light weight of membrane nitrogen generators allow them to easily adapt to these space-constrained environments, and their simple maintenance requirements make them easy to maintain in mobile or remote areas.

For companies with fixed installation sites, certain requirements for equipment maintenance convenience, but able to bear relatively high maintenance costs, PSA nitrogen generators, although having a larger footprint and relatively complex maintenance, can ensure stable operation and effective maintenance through reasonable equipment layout and personnel training.

Membrane and PSA nitrogen generators each have their own advantages in industrial nitrogen production. When choosing, companies need to comprehensively consider nitrogen purity, production scale and flow rate requirements, cost factors, installation space, and maintenance convenience, weighing the pros and cons to select the nitrogen generation equipment most suitable for their production needs, providing strong support for efficient production and sustainable development.

Other areas

Oil storage and pressurized pipeline cleaning and purging of oil and gas wells, nitrogen sealing, nitrogen displacement, solvent recovery.

Used for food preservation and grain storage, pest control, food drying and sterilization, quick freezing of food, etc.

Provide the necessary gas raw materials for the preparation of new energy materials, battery production, and create an inert gas environment.

Ensure the manufacturing of electronic components and the stable operation of equipment, providing gas support for maintenance, combustion assistance, cooling, and other aspects related to thermal power generation equipment.

Nitrogen generator: Prevents oxidation, inhibits bacterial growth, and produces odors in biopharmaceuticals, providing protection throughout the process. Oxygen generator: Provides an oxygen-rich environment.

When signs of fire occur in the goaf or other locations, nitrogen injection is needed for fire prevention. The nitrogen device is lowered into the mine. It is used for annealing protective gas and sintering.

Used in the aerospace composite field, providing the necessary inert atmosphere for the molding and reinforcement processes of large carbon fiber composite wings.

Provide protection for the safety of oil and gas reserves, prevent oxidation, nitrogen sealing, and ensure dust suppression, fire prevention, and nitrogen sealing for coal reserves.