Nitrogen generators can bring transformative help to the development of the powder coating industry

Nitrogen generators can provide the required nitrogen for the powder coating industry, thereby improving production efficiency

In the powder coating industry, which is constantly pursuing high-quality and efficient production, nitrogen generators, as key equipment, are playing an increasingly important role. By providing high-purity nitrogen, they create a more ideal environment for the powder coating process, effectively solving many industry pain points and significantly improving product quality and production efficiency.

I. Current Status and Challenges of the Powder Coating Industry

With the rapid development of the manufacturing industry, powder coating, as an environmentally friendly and efficient surface treatment technology, is widely used in many fields such as automobiles, home appliances, and construction. However, the industry faces some challenges in its production process. Moisture, impurities, and unstable temperature and humidity in traditional compressed air systems can negatively affect the quality of powder coatings, leading to issues such as bubbles, sagging, and insufficient adhesion. In some application scenarios with extremely high demands for coating quality, such as the coating of high-end automotive parts and aerospace components, existing coating processes struggle to meet increasingly stringent quality standards.

II. Specific Application Scenarios of Nitrogen Generators in the Powder Coating Industry

(I) Spraying Environment Control

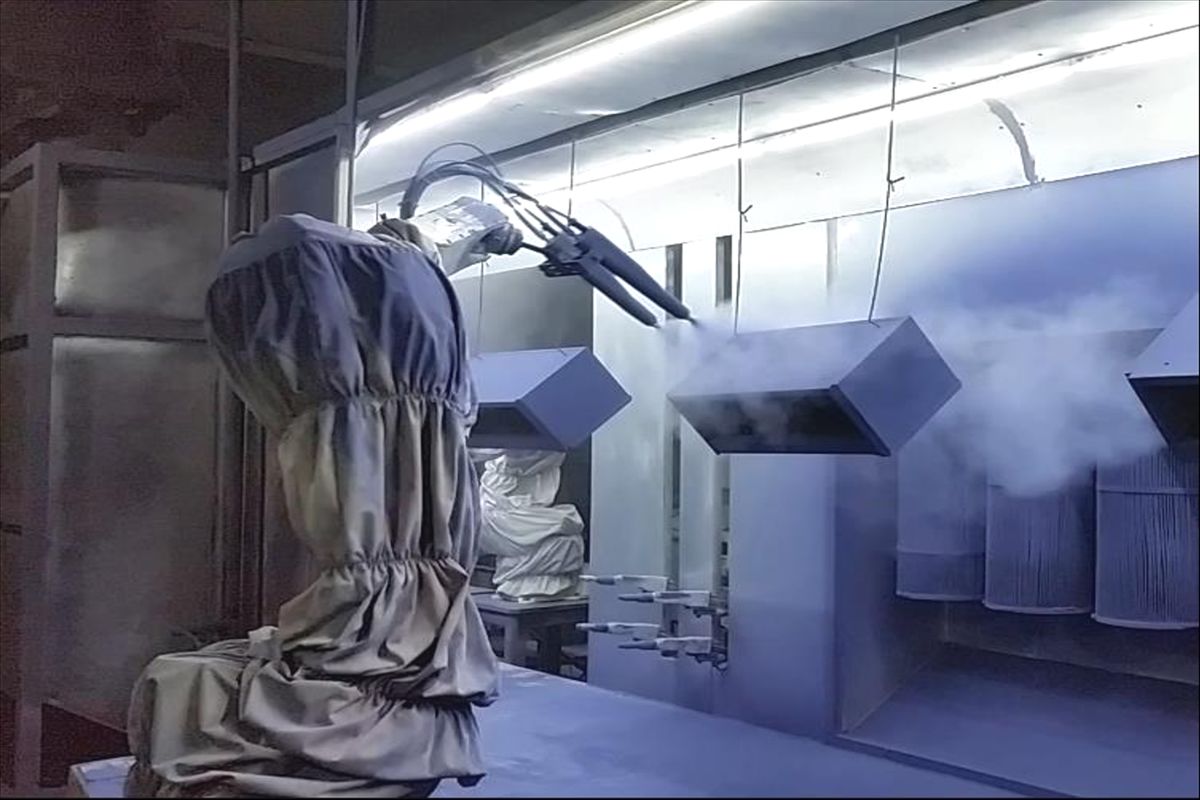

During the powder coating process, filling the spray booth with high-purity nitrogen can effectively reduce the oxygen content inside, creating an inert environment. This prevents powder oxidation during spraying, avoiding issues like coating color changes and performance degradation caused by oxidation, especially suitable for metal powder coating with extremely high demands on coating quality, such as surface treatment of stainless steel and aluminum alloys.

Nitrogen has dry and stable characteristics and can regulate the humidity and temperature inside the spray booth. By precisely controlling the flow and temperature of nitrogen with a nitrogen generator, the humidity and temperature of the spraying environment can be ensured to remain within the optimal range, reducing coating defects caused by environmental factors. For example, in humid weather or high-humidity areas, using nitrogen can effectively prevent issues such as bubbles and pinholes in the coating caused by moisture.

(II) Powder Conveying and Fluidization

Using nitrogen as a carrier for powder conveying, compared to traditional compressed air, nitrogen has higher stability, allowing the powder to maintain a uniform flow rate and dispersed state during conveying, reducing powder agglomeration and blockage, and improving the efficiency and stability of powder conveying. This is crucial for achieving automated and continuous powder coating production. After introducing nitrogen conveying to an automated powder coating production line, the number of downtimes due to powder blockage decreased by 80% per month.

In the powder fluidization hopper, introducing nitrogen can fluidize the powder better, making it exhibit a liquid-like flow state. This allows the powder to be sprayed more evenly by the spray gun, improving the atomization effect and powder coating rate, thereby achieving a more uniform and dense coating. According to tests, after using nitrogen fluidization, the powder coating rate increased by an average of 15%-20%.

(III) Prevention of Dust Explosions

During the powder coating process, airborne powder mixed with air can easily cause dust explosions if it encounters an ignition source or static electricity. The nitrogen provided by a nitrogen generator can be used to dilute the oxygen concentration in the spray booth, keeping it below the explosive limit concentration for dust, thereby effectively reducing the risk of dust explosions and ensuring production safety. This application of nitrogen generators is particularly important in large-scale powder coating production lines or locations with extremely high safety requirements, such as coating for mining machinery and chemical equipment.

III. Advantages of Nitrogen Generators in the Powder Coating Industry

(I) Improved Coating Quality

By creating a stable and pure spraying environment, nitrogen generators can significantly reduce coating defects and improve the coating's adhesion, flatness, and corrosion resistance, elevating product surface quality to a higher level and meeting the stringent requirements of the high-end market for product appearance and performance. Data shows that after using nitrogen generators, the overall good product rate of coatings can increase by 20%-30%.

(II) Reduced Production Costs

On one hand, it reduces rework and scrap rates caused by coating quality issues, lowering raw material and labor costs; on the other hand, it improves powder utilization and reduces powder waste, thereby lowering production costs. According to statistics, after using nitrogen generators, powder consumption can be reduced by 10% - 30%, with some enterprises saving over a million yuan in raw material costs annually.

(III) Enhanced Production Efficiency

Stable powder conveying and fluidization effects, along with efficient spraying environment control, make the spraying process smoother and significantly improve production efficiency. At the same time, it reduces equipment downtime due to maintenance and failures, further enhancing production efficiency. For example, after a certain home appliance coating company introduced nitrogen generators, the daily production capacity of its production line increased by 35%.

(IV) Enhanced Safety

Effectively prevents dust explosions, creating a safer production environment for enterprises and reducing potential losses from safety accidents. With increasingly strict safety regulations, nitrogen generators safeguard enterprise production safety.

IV. Case Study

Before introducing Polyke nitrogen generators, a large automotive parts manufacturing enterprise frequently experienced unstable coating quality during powder coating, with a scrap rate as high as 15%. After adopting nitrogen generators, by controlling the oxygen content and humidity in the spraying environment, defects such as bubbles and sagging in the coating significantly decreased, reducing the scrap rate to below 5%. At the same time, powder utilization increased by 20%, saving hundreds of thousands of yuan in raw material costs annually. Production efficiency also significantly improved, with the capacity of the coating production line increasing by 30%.

V. Future Outlook

As the powder coating industry's demands for product quality and production efficiency continue to increase, the application prospects for nitrogen generators in this industry will become even broader. In the future, nitrogen generators will develop towards intelligence, high efficiency, and energy saving, providing higher quality and more stable nitrogen supply for the powder coating industry, assisting the industry in achieving sustainable development.

In summary, nitrogen generators, as effective assistants in the powder coating industry, have brought numerous advantages to the industry through their applications in spraying environment control, powder conveying and fluidization, and dust explosion prevention, effectively addressing the challenges faced by the industry. It is believed that in the near future, nitrogen generators will play an even greater role in the powder coating industry, driving the industry towards a new stage of development.

Other areas

Oil storage and pressurized pipeline cleaning and purging of oil and gas wells, nitrogen sealing, nitrogen displacement, solvent recovery.

Used for food preservation and grain storage, pest control, food drying and sterilization, quick freezing of food, etc.

Provide the necessary gas raw materials for the preparation of new energy materials, battery production, and create an inert gas environment.

Ensure the manufacturing of electronic components and the stable operation of equipment, providing gas support for maintenance, combustion assistance, cooling, and other aspects related to thermal power generation equipment.

Nitrogen generator: Prevents oxidation, inhibits bacterial growth, and produces odors in biopharmaceuticals, providing protection throughout the process. Oxygen generator: Provides an oxygen-rich environment.

When signs of fire occur in the goaf or other locations, nitrogen injection is needed for fire prevention. The nitrogen device is lowered into the mine. It is used for annealing protective gas and sintering.

Used in the aerospace composite field, providing the necessary inert atmosphere for the molding and reinforcement processes of large carbon fiber composite wings.

Provide protection for the safety of oil and gas reserves, prevent oxidation, nitrogen sealing, and ensure dust suppression, fire prevention, and nitrogen sealing for coal reserves.